Richard Derek McDonald, PE

Derek has demonstrated proficiency as a Project Manager, Quality Control Manager, and Safety Representative, with over 20 years of experience in the construction industry. He most frequently works on the design and construction management for underground projects—ranging from roadheader and mechanical excavation, to microtunneling. In addition to his experience in the construction of complex tunnel infrastructure is the incorporation of various earth support systems for these excavation projects. Mr. McDonald has utilized nearly every conventional earth support of excavation system and technique for tunnel, shaft, and portal work.

Derek's Featured Projects

Tunnel Stabilization and Sewer Pipeline Phases 1-4 | Laguna Beach, CA

Project Manager

The South Coast Water District awarded Drill Tech this four-phase project, completed over the span of seven years, to provide new sewer tunnel access and install a new 24" sewer main. Drill Tech performed 10,000 LF of open face roadheader excavation supported by steel sets and shotcrete as well as constructing a 20′ diameter 100′ deep shaft and 300′ long access tunnel underneath the coast highway to intercept and provide access to the sewer tunnel area. The challenging geotechnical environment of this site included a 500′ section through mixed face rock and fill with considerable water that required hand mining as to not affect the above line apartment complex.

Terminal Hill Tunnel and Shaft | Sylmar, CA

Project Manager

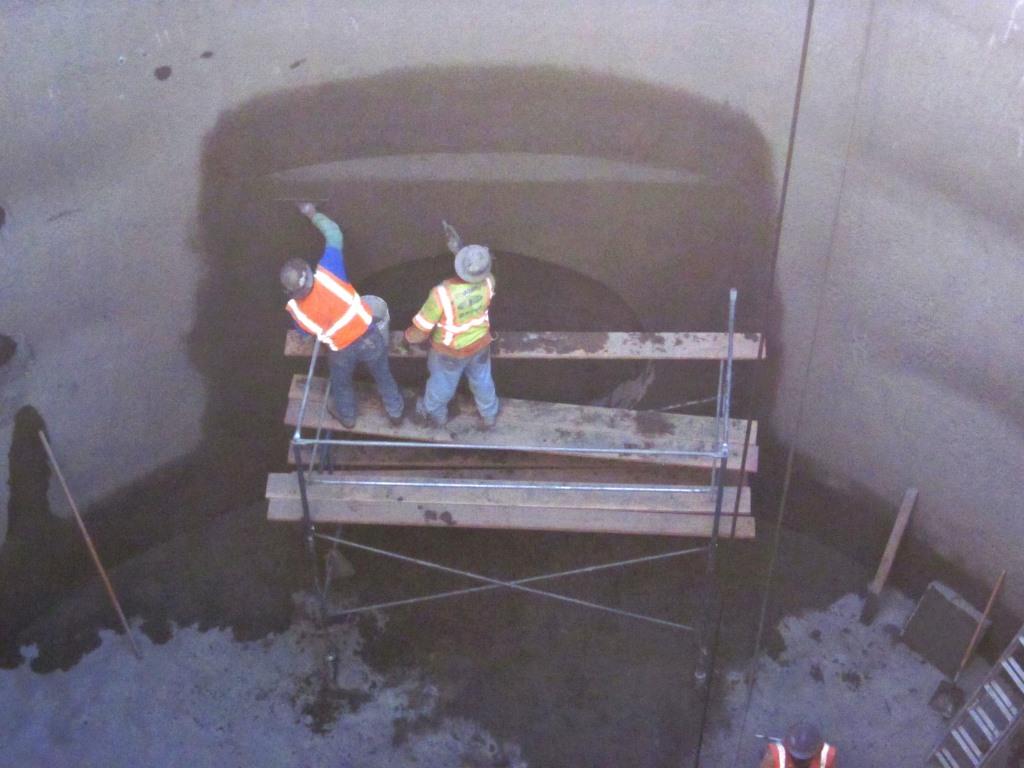

The Terminal Hill Project for LADWP consisted of constructing a new tunnel and shaft network to realign the second LA aqueduct that was damaged during, and continually repaired since, the 1994 Northridge earthquake. The 600′ tunnel was constructed through sandstone using roadheader and SEM techniques with temporary steel sets and shotcrete. Portal development for the tunnel was provided using a temporary soil nail shoring system. The 600′ deep shaft was constructed through sandstone using SEM techniques employing a shank sinking platform with roadheader attachment and temporary support using grouted liner plate. A permanent reinforced CIP liner was then installed in both the shaft and tunnel.

San Ramon Canyon Storm Drain Project | Rancho Palos Verdes, CA

Project Manager

Drill Tech constructed a 350′ slant drain tunnel using a digger shield supported by continuous driven steel casing and a 2,000′ rib and lag tunnel using an open face TBM supported by steels rib and lagging. Additional work included constructing the inlet and outlet structure. These tunnels were constructed using modified SEM techniques supported by TBM equipment. The tunnels were constructed to provide a conduit for storm water to be more efficiently transported to the ocean in areas known to be prone to landslides initiated by water inundation. This work was performed just south of the Portuguese bend area of Rancho Palos Verdes, CA.

Santa Ana River Interceptor | Yorba Linda, CA

Project Manager

Drill Tech constructed 4 each launching and receiving pits to support an MTB operation. Shaft sizes and depths ranged from 16′-36′ and 40′-75′ respectively. Shaft support means and methods were dictated by different ground types and water expected. Shaft support in two (2) cases comprised of shotcrete and lattice girder installed using SEM techniques. The other two (2) cases a pre-excavation cut off wall system was installed due to expected water from the adjacent Santa Ana River. Cutter soil mix panels were installed at the launch pit side of the Santa Ana River Crossing and secant piles were installed at the receiving pit side of the river crossing, prior to initiating excavation.

Project Manager, Drill Tech Engineer

Vulcan Materials contracted Drill Tech to build a 12′ diameter by 268′ tunnel for the relocation of a conveyor belt subsurface that constituted a larger reconfiguration of the aggregate mine. Drill Tech constructed the tunnel with an open face digger shield and installed steel ribs and channel lagging for support. This job included the design and construction of portal shoring to create access via permanent soil nail wall. In order to launch the machine from a portal Drill Tech designed a jacking frame using wide flange beams secured to the ground surface using micropiles.