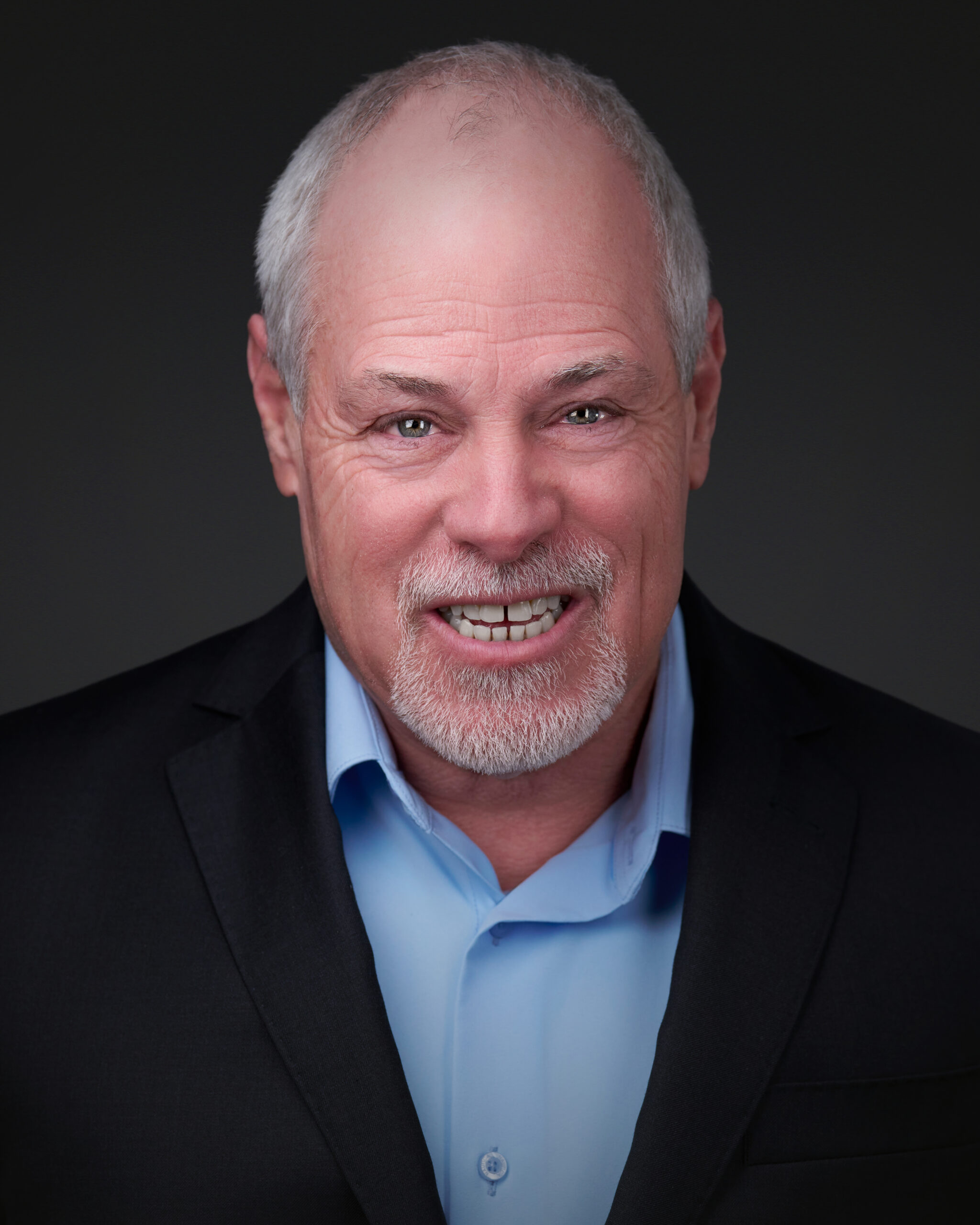

Trey Martin

Trey possesses more than 35 years of experience in the underground construction industry. He has provided oversight as a Superintendent and Foreman for mining and tunneling projects, often performing gas testing and safety representative duties. Mr. Martin’s roadheader and drill/blast capabilities, coupled with ample ground support installation, enable him to approach a variety of site conditions with the appropriate response for both safety and quality of the project’s outcome.

Trey's Featured Projects

Harvest Water – Franklin/Eschinger Distribution Pipeline Project | Morgan Hill, CA

gas tester / safety representative

This project consisted of two separate microtunnel drives using 78" OD Trinity Tri-Loc Spiral Welded Steel Casing and installing either 60" WSP at the Railroad Crossing or 66" WSP at the Stone Lake Creek Crossing. The microtunnel drive lengths are 181 LF and 344 LF.

Merced Irrigation District Two Bar Tunnel No. 1

Project consisted of enlarging an existing 1581' tunnel from 13.5' to 19'. The team excavated 360' of upstream portal then excavated 60' of downstream portal, installing rock dowels and shotcrete slopes for both. 6" shotcrete was installed to support the entire length of the tunnel, excavate the invert to competent rock, compact and backfill, and pour 1581' of concrete slab.

Coast Road Sinkhole Repair

Project included 300' construction of a 12' diameter soft ground tunnel performed with digger shield. The tunnel had a 100' radius turn just before reaching the railroad culvert which was the underground termination. The digger shield was built at a shop in Bakersfield and abandoned within the tunnel because the culvert was too small to recover it. The final lining was 84" dia. reinforced concrete pipe which was carried in and grouted in place.

Carlsbad Destination Plant – Macario Tunnel | Carlsbad, CA

This project included the excavation and support for 700' of a 10' diameter horseshoe tunnel with steel sets and shotcrete using roadheader and 150' of a 10' diameter tunnel with liner plates and grout backfill using hand mining methods. Excavation and support of 80' deep x 17' diameter shaft and elbow area was performed with ring beams and shotcrete utilizing a Cryderman shaft mucker. Additional scopes included built bulkheads and placed cellular backfill.